Anjing Road, Xiaolan, Zhongshan, Guangdong, China

info@mes-drive.com

08.00 AM-09.00 PM

Introduction

In December 2023, the world gathered in Dubai for the 28th Conference of the Parties (COP28), a high‑profile UN climate summit that sent shockwaves across politics, business and technology circles. Amidst discussions on net‑zero targets, forest preservation and clean energy, one theme stood out: the electrification of transportation. Governments pledged billions for electric vehicle (EV) infrastructure, while tech giants announced next‑generation battery packs and autonomous robots. At first glance, the summit sounded like talk about cars and drones—yet a silent hero underpinning this transformation is the humble reducer motor, also known as a gear motor. Though often overlooked by the public, these compact machines stitch the promise of COP28 into reality by turning electrical energy into reliable motion for thousands of electric devices.

Gear Motors: The Backbone of Electric Mobility

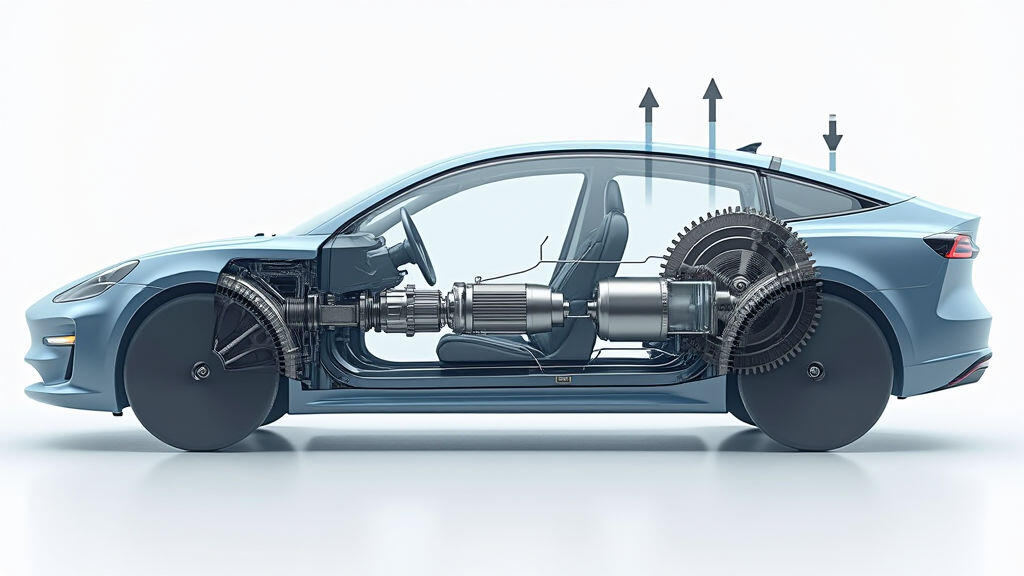

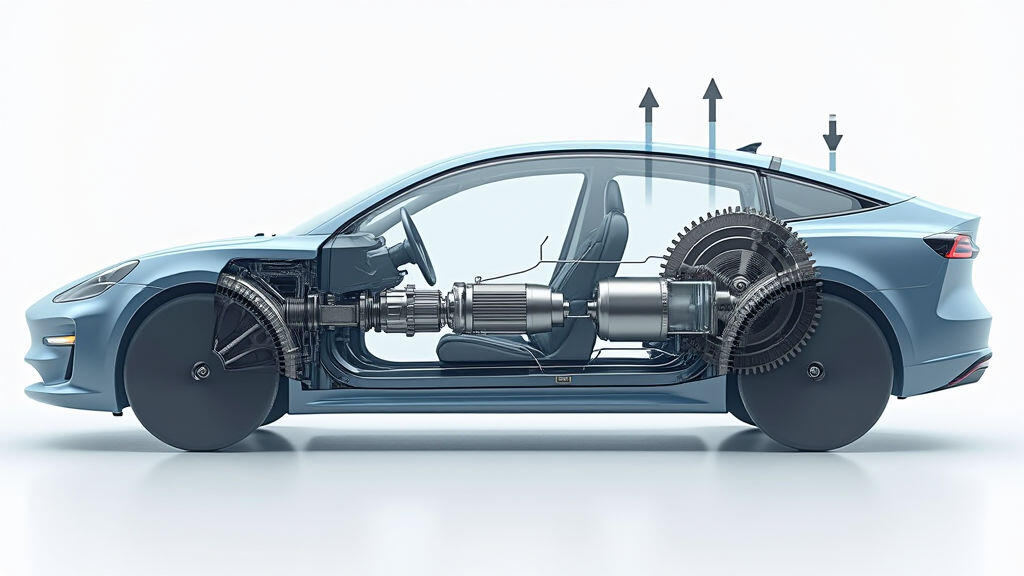

A reducer is a compact assembly that couples an electric motor with a gear train, translating high‑speed, low‑torque electrical output into slower, high‑torque mechanical motion. This perfect pairing makes gear motors essential for the everyday vehicles that COP28 champions.

From Urban Streets to Rural Roads: Supporting the EV Pipeline

The automotive sector is charting a historic transition. According to a January 2024 report by the International Energy Agency, electric cars will grow from 4% of global sales in 2022 to an estimated 30% by 2030. This surge means that manufacturers can no longer afford to use bulky, falling‑off electric motors. Gear motors provide the compact size, low space requirement, and energy‑efficient torque conversion that modern vehicle design needs.

Furthermore, gear motors fit neatly into the modular approach seen at COP28’s “New Mobility” track. Modular powertrains—where a single motor‑gear unit can be swapped or upgraded—simplify electric vehicle maintenance and repair, a requirement many low‑ and middle‑income countries reported during summit panels.

Sustainable Energy and Renewable Integration

COP28 also highlighted the critical link between clean electricity and green transport. One hot topic was the expansion of renewable‑energy–driven charging stations, particularly those powered by solar arrays. Gear motors don’t just act inside vehicles; they are essential for feeding renewable generators. Small wind turbines, for instance, use gear motors to convert the low‑speed rotation of the blades into usable grid‑level frequency. The same principle applies to solar‑powered pumps, water treatment plants, and even the push‑buttons that power streetlights—most of which now contain invisible gear motors.

In a world where initial grid capacity often lags behind renewable output, these gear motors serve as a bridge. They regulate power draw, maintain torque during peak generation, and keep the entire system stable—an invisible but vital element that ensures solar swells turn into usable energy for EV charging.

Industry Innovation: Compact, Smart, and Responsive

COP28 set a clear reminder: “The future of transport is powered by software as much as hardware.” Latest gear motor designs now integrate sensor suites and micro‑controllers, enabling real‑time torque adjustments, fault detection, and predictive maintenance. This “smart” form factor allows vehicles to calibrate stationary torque for parking brake systems while delivering peak torque during road bursts—ensuring smoother rides and higher safety outcomes.

Add to that the push for “in‑house” manufacturing seen at the summit. Asian automakers are investing in domestic gear motor fabs to reduce supply‑chain risks associated with rare earth metals. In the United States, a new policy announced at COP28 encourages local production of essential motor components, potentially spurring a renaissance of regional gear‑motor plants.

Economic Momentum: A Hedge Against Material Volatility

The surge in EV demand has far outpaced the supply of pricey inductive motors, tightening global supply chains. Gear motors, by contrast, often rely on more abundant steel, aluminum, and standard stator designs. As a result, they present a lower‑cost alternative that can be mass‑produced without bottlenecking at the supply‑chain level. Venture‑capital interest is already flowing into mediumsized firms developing ultra‑compact, high‑efficiency gear motors specifically for micro‑mobility and industrial automation.

At COP28, one notable instance of this trend was a startup presenting a 10 kW gear motor that could fit into a two‑wheeled autonomous delivery robot—all on a footprint smaller than a credit card. The demo was met with enthusiastic applause, cementing the idea that gear motors provide the “fast track” to mass deployment.

Conclusion

COP28’s focus on electrifying transportation—through infrastructure growth, software integration, and local manufacturing—doesn’t just aim to woo headlines; it presents a real pathway toward a decarbonized economy. Behind every electric car, scooter, and autonomous robot lies the gear motor, a quietly powerful device that bridges electric power and mechanical motion. Its compact size, reliability, and adaptability fuel the vehicles, woken up by solar panels and fed by clean wind. As governments commit to net‑zero goals and the automotive sector scales upward, the demand for gear motors will only increase. In the next decade, these humble machines will become the unsung heroes of the transportation revolution, turning the promises of COP28 into everyday reality.

Leave A Reply

Your email address will not be published. Required fiels are marked